News

During sewer pipeline inspections, large municipal pipes require special attention. These multi-million dollar investments should be regularly inspected along every foot, bend, and lateral to ensure structural integrity, consistent operational performance and to prevent catastrophic failures.

And within many of these pipe systems, it’s not enough to simply lower a camera for a visual inspection. Instead, municipalities require detailed data sets to understand the extent of corrosion of the pipeline material year-over-year and whether sediment levels are building up reducing designed flow capacity and potentially adding to the generation of destructive gases such as hydrogen sulfide.

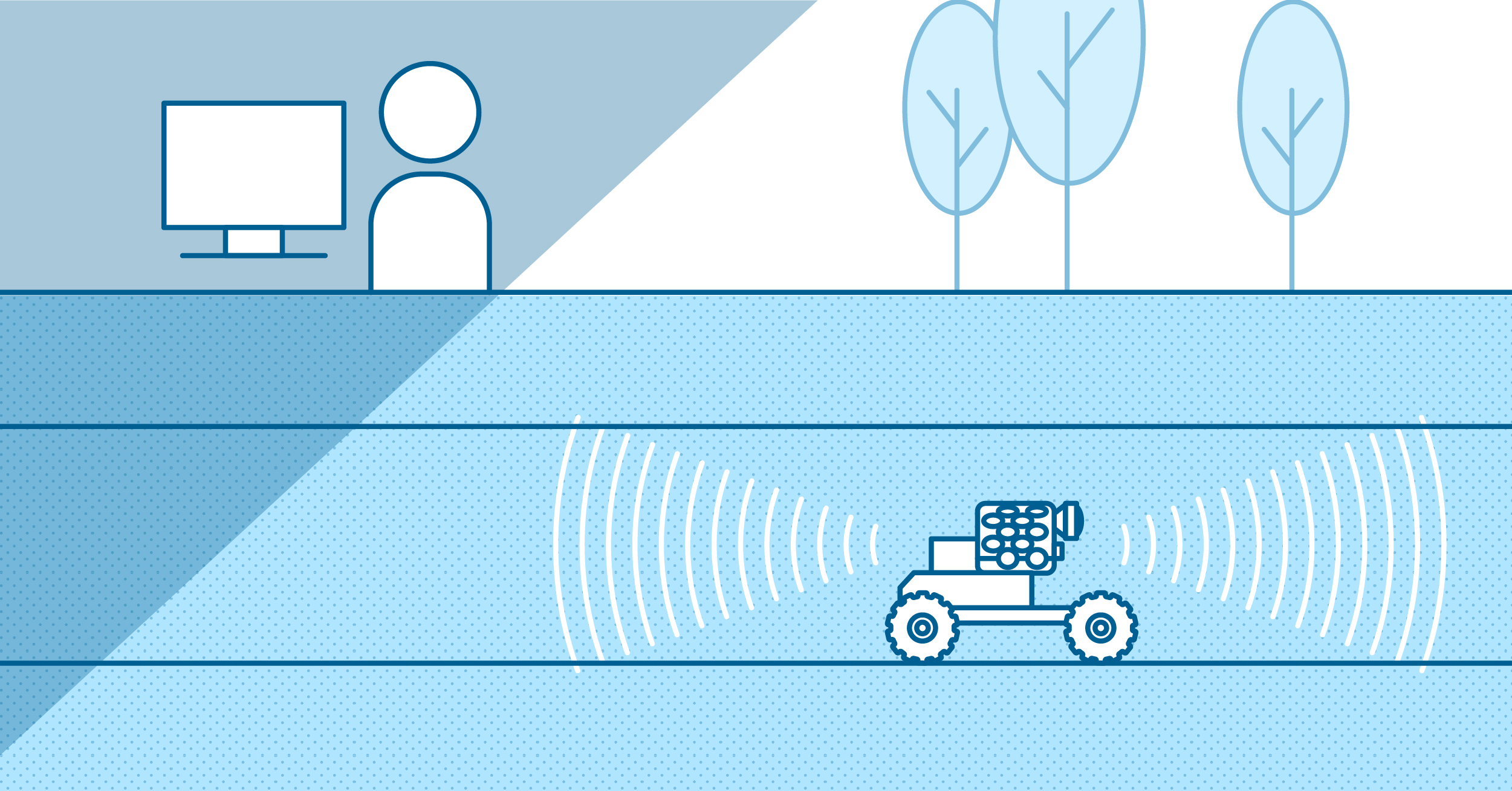

That’s why Multi-Sensor Inspection equipment like the CUES SoLID FX is so important. By combining data from the digital sonar, CCTV camera and 2D-LiDAR, engineers and utility owners can now make decisions based on these data that was not available in the past. The SoLID FX equipment delivers detailed reports on pipe deterioration, blockages, and more—all important details when planning and preparing for costly repairs, essentially providing engineering-level quality data to decision-makers.

Using the SoLID FX For Pipe Inspection & Maintenance

Some of the major benefits of using multi-sensor pipe inspection equipment like the SoLID FX include:

- SONAR - The HD SONAR system within the SoLID FX displays debris levels and pipe capacity in each section of pipe, providing a detailed condition assessment for your decision makers. SONAR (Sound Navigation and Ranging) and SONAR equipment can also reduce the time and expense of each inspection job, giving your team the ability to cover more pipe in less time while generating enough data to estimate labor costs for debris cleaning and removal efforts

- LIDAR - The LIDAR (Light Detection And Ranging) system produces critical corrosion/pipe wall erosion data and allows visuals of laterals, open joints, holes, and more through the use of a rapidly pulsing laser. This is especially useful for sewer interceptor/trunk sanitary sewer inspections. Plus, with the ability to switch between 2D LIDAR and 3D LIDAR, the SoLID FX can create 3D models of pipe systems as it crawls through them.

- Video Inspection - The SoLID FX supplements the SONAR and LIDAR with a digital sewer camera inspection. Between the SONAR, LIDAR, and video inspection, the SoLID FX becomes a three-in-one viewer that constantly sends information back to the user so that data quality is ensured and performance specifications are maintained.

The SoLID FX comes equipped with a digital fisheye camera so teams can capture every pipe defect without panning, tilting, or zooming. Inside larger pipes, the digital fisheye camera can be exchanged for one with optical zoom capabilities. - Lens-Clearing System - The SoLID FX’s lens-clearing system removes water droplets and debris from the camera and LIDAR system, ensuring clear visuals and accurate data at all times.

- Large Pipe Inspection - The SoLID FX is designed for pipes 24” and larger, which makes it a terrific sewer pipe inspection camera choice for large municipalities and any area containing large pipes.

- Long Reach - The SoLID FX can be deployed up to 3,000’ (914 m) from a CUES Steerable Mudmaster or more than a mile (up to 5,400’ or 1,646 m) on a CUES SFX FLOAT. That allows your team members to inspect more pipe from a single location—saving time and and reducing the need for multiple mobilizations to other pipeline access points.

- Data Points - With so many sophisticated capabilities, technology like the SoLID FX can measure:

- The exact diameter of the pipe—based on the impact of corrosion and how the pipe is gradually eroding over time. This data is critical in pipeline remaining life evaluations/modeling

- The amount of sediment in the pipe—and how that sediment is increasing or decreasing over time. Sediment volumes can also be utilized in determining impacts to flow capacity issues

- The exact angle, pitch, and length of individual pipe sections

- Critical data necessary for designing pipe liners and/or preparing for crucial repairs

Learn More About Multi-Sensor Inspection & Pipe Profiling Equipment

To learn more about our Multi-Sensor Inspection and Profiling Systems, check out:

Contact us for more information.