Below The Surface

Sonar in the Sewer

Here's what you need to know.

Sonar? In the sewer?

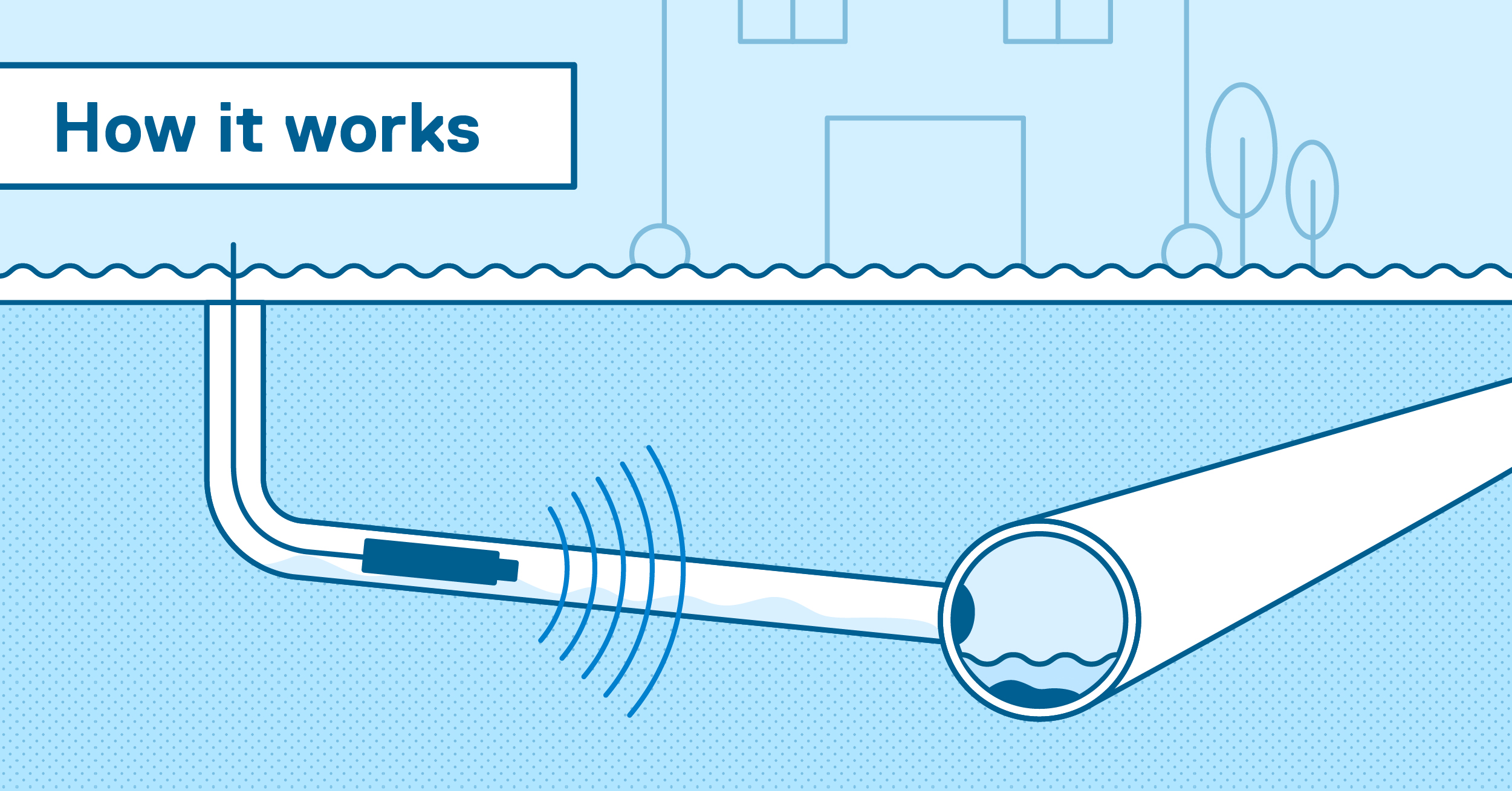

Sonar is short for Sound Navigation and Ranging—a great insight to what it does. Sonar uses sound to find objects and detect how large and how far away they are. Sonar is especially helpful in places where it’s hard to see; think of bats using sonar at night or submarines using sonar in the depths of the open ocean.

Sewers are dark places typically full of water and full of obstacles. This makes sonar a perfect tool for professionals working underground.

Why sonar and not cameras?

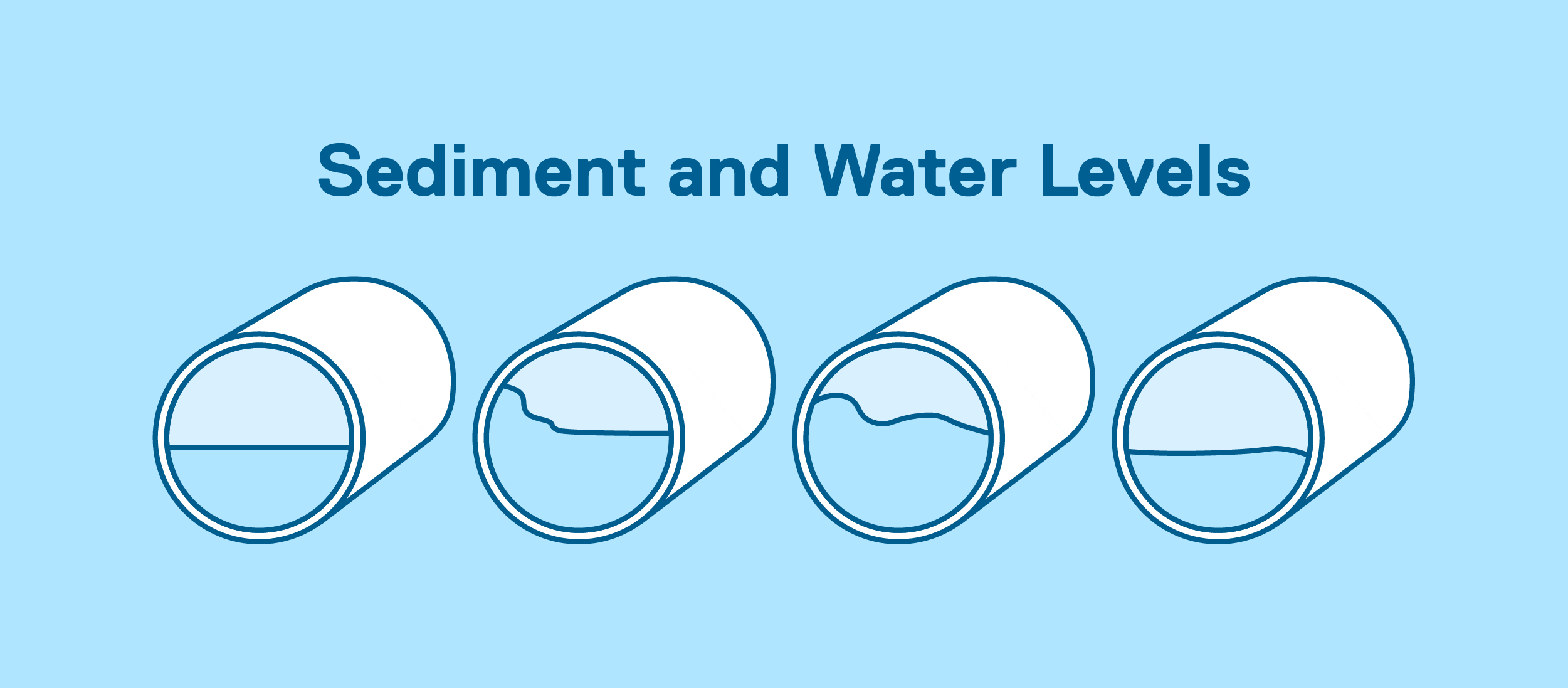

Sewer pipe cameras can also be a solid choice for sewer inspections, but they can be hampered by one major disadvantage: it’s not easy to get a good visual in water with any level of sediment and/or debris. And while you could bypass a section of sewer and inspect it while dry, the process adds a level of complexity and expense that can be hard to justify. With sonar pipe inspection, you don’t need to empty the pipe to ‘see’ what’s in there.

How does sonar sewer inspection equipment help inspectors?

Because it can inspect pipes even when they’re still in operation, sonar pipe inspection can help reduce the time and expense of each job. Sonar sewer inspection equipment also excels at giving accurate data on pipe cross-section properties, pipe deformation, silt level, obstructions, deviations and more. It can also give a clearer picture of sediment levels in pipes to highlight areas where cleaning is needed—or where removal can be delayed.

When integrated with mapping software, sonar pipe inspection can show which areas of a given system are the most in need of maintenance and, by measuring the amount of sediment in a given section of pipe, how much sediment needs to be removed. This level of detail allows a municipality to be much more exacting—giving them a clear picture of where crews need to go and how much work is to be done.

Additionally, using the amount of sediment in a section of pipe as a baseline is a considerably more precise way to measure how well a sediment removal project has been. Sonar profiling is the only way to get an accurate picture of the level of sedimentation in a section of pipe. And if service crews don’t know how much sediment they need to remove prior to maintenance work, they’ll have no exact way of knowing when they’re done—and indecision like this is always expensive.

What CUES, Inc. knows about it:

As the only supplier who currently offers a sonar unit to be used for pipe inspection, we consider ourselves to be an expert in sonar inspection equipment and sonar profiling. We’ve improved the ability for our customers to judiciously deploy their pipe maintenance resources. Our sonar pipe inspection products provide our customers a one-stop shop that they can rely on. We always aim to make inspectors jobs' easier—by offering whatever they need to do their job the right way.