Below the Surface

Multi-Sensor Inspection Equipment 101

Municipal sewers and pipelines are multi-million dollar investments that require regular inspections, maintenance, and repairs to ensure consistent performance and avoid costly replacements.

But there are plenty of challenges that threaten a sewer’s operations and structural integrity. Excess inflow and infiltration create overflow, threatening communities and the local environment. Contaminants, overuse, and shifting surroundings place additional stress on the pipe, potentially causing leaks. Budget cuts slash manpower and hamper inspection schedules, allowing emerging problems to grow unnoticed.

The hazards are constant.

Fortunately, municipalities can remain proactive with multi-sensor inspectional equipment, which is specifically designed to provide rich data points on a sewer or pipeline’s internal health.

What Is Multi-Sensor Inspection Equipment?

As the name suggests, multi-sensor inspection equipment uses multiple sensors to check the health of a pipe. These sensors may include:

1. SONAR - SONAR (Sound Navigation and Ranging) displays debris levels and pipe capacity in each section of a pipe, providing two major benefits:

- a detailed condition assessment for decision-makers

- the ability to reduce the time and expense of each inspection job.

SONAR pipe inspection’s speed and accuracy allow your team to cover more pipe in less time while generating enough data to estimate labor costs for clean-up efforts.

2. LIDAR - LIDAR (Light Detection And Ranging) allows Engineering Level Detail in determining corrosion and defect analysis within the pipelines, including mis-aligned joints, breaches, and holes within the pipeline. It also allows one to see up into laterals for defect analysis through the use of a rapidly pulsing laser, which is especially useful for sewer corrosion analysis inspections.

The latest LIDAR technologies can even switch between 2D LIDAR and 3D LIDAR, which gives you the ability to create 3D models of your pipe systems.

3. Video Inspection - Many multi-sensor equipment designs incorporate either a digital fisheye camera (to capture pipe defects without panning, tilting, or zooming) or an optical zoom pan and tilt pipe camera (to see deep into a pipeline) so operators can view the inside of a sewer from the safety of an above-ground location with the use of a pipe inspection camera system.

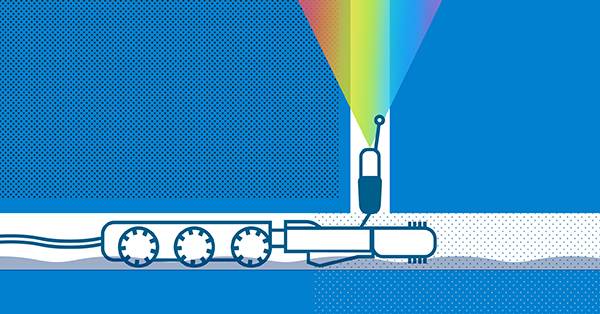

How Does Multi-Sensor Inspection Equipment Work?

Multi-sensor equipment is placed inside a manhole during a manhole inspection or other sewer entrance and is lowered into the pipeline. The multi-sensor platform (Digital Sonar, 2D/3D-LiDAR, and CCTV camera) provided either on a floating platform or a robotic crawler, connects to the control room of the CUES truck where real-time sensor returns are reviewed by the on-site data analyst who remotely controls the equipment. This ensures that the collection of the Multi-Sensor data maintains a very stringent and delivers a high level of data quality.

As the equipment crawls through the pipe, it collects a variety of data points, including:

- The amount of sediment in the pipe. Over multiple pipeline inspections, a team can track how much sediment is accumulating over time

- The exact diameter of the pipe. With enough inspections, a team can calculate how quickly the pipe is eroding over time

- The exact angle, pitch, and length of individual pipe sections

- Critical data necessary for designing pipe liners or preparing for crucial repairs

Further analysis is performed on the field collected MSI data and is provided within a live 4-and-1 report showing real-time sensor returns with CCTV video. Additionally, a field report discussing the results of the MSO inspection is also provided to the client with informations such as:

- Cumulative sediment segment graph

- Lidar Corrosion graph

- Identification of in-pipe defects and other problematic issues within the pipeline

- Specific areas of interest

What Are Examples of Multi-Sensor Inspection Equipment?

While we offer a variety of options when it comes to multi-sensor inspection equipment, we have three major products:

1. SoLID FX - The SoLID FX combines the power of SONAR, LIDAR, and video for multiple data sets that provide detailed information about the current performance of your sewers and pipes. Analysis can be performed in a CCTV inspection vehicle or on a remote computer.

2. 3D-LiDAR -by recording and aligning point cloud in-pipe data, Cues is able to provide Bend-analysis (determination of angles, Cross-Sections, Defect Analysis, and Geo-Location. This information provides critical Engineering Level Detail to engineers and municipalities/owners to make decisions on rehab methods and liner design.

3. CATVS - CATVS stands for Combined Analog TV and SONAR, and it works exactly as you’d expect: The device combines the optical clarity of video with the data-driven insights of SONAR.

Find Multi-Sensor Inspection Equipment From CUES

If you need assistance finding the right equipment for your team, contact us. Our experts are standing by to rapidly diagnose and solve your problem with industry-leading equipment.