|

|

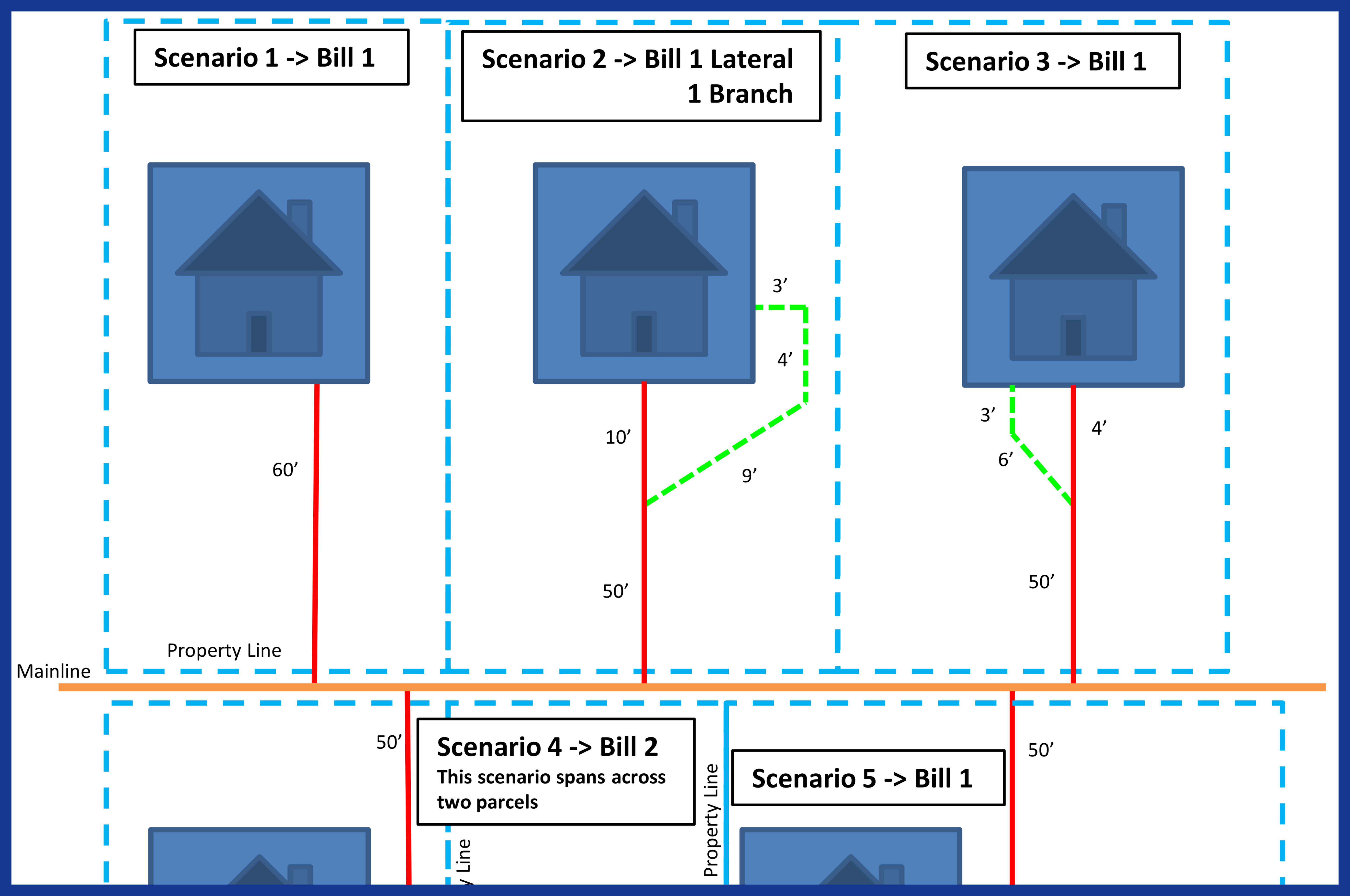

Orchestrate all phases of the construction process:

- Door hanger notifications

- Gas meter assessments

- Pre-Locates, Legacy inspections, Post Locates

- HDD Drilling; Excavation

- Gas Service Connection

- Patching and paving; much more

|

| |

|

|

|

|

Wirelessly Synchronize Task Workflows

- Customer notifications

- Meter assessments

- Pre-locates, legacy inspections, post locates

- Excavations, patching and paving

HDD drilling

- Final QA Inspections, etc.

|

| |

|

|

|

|

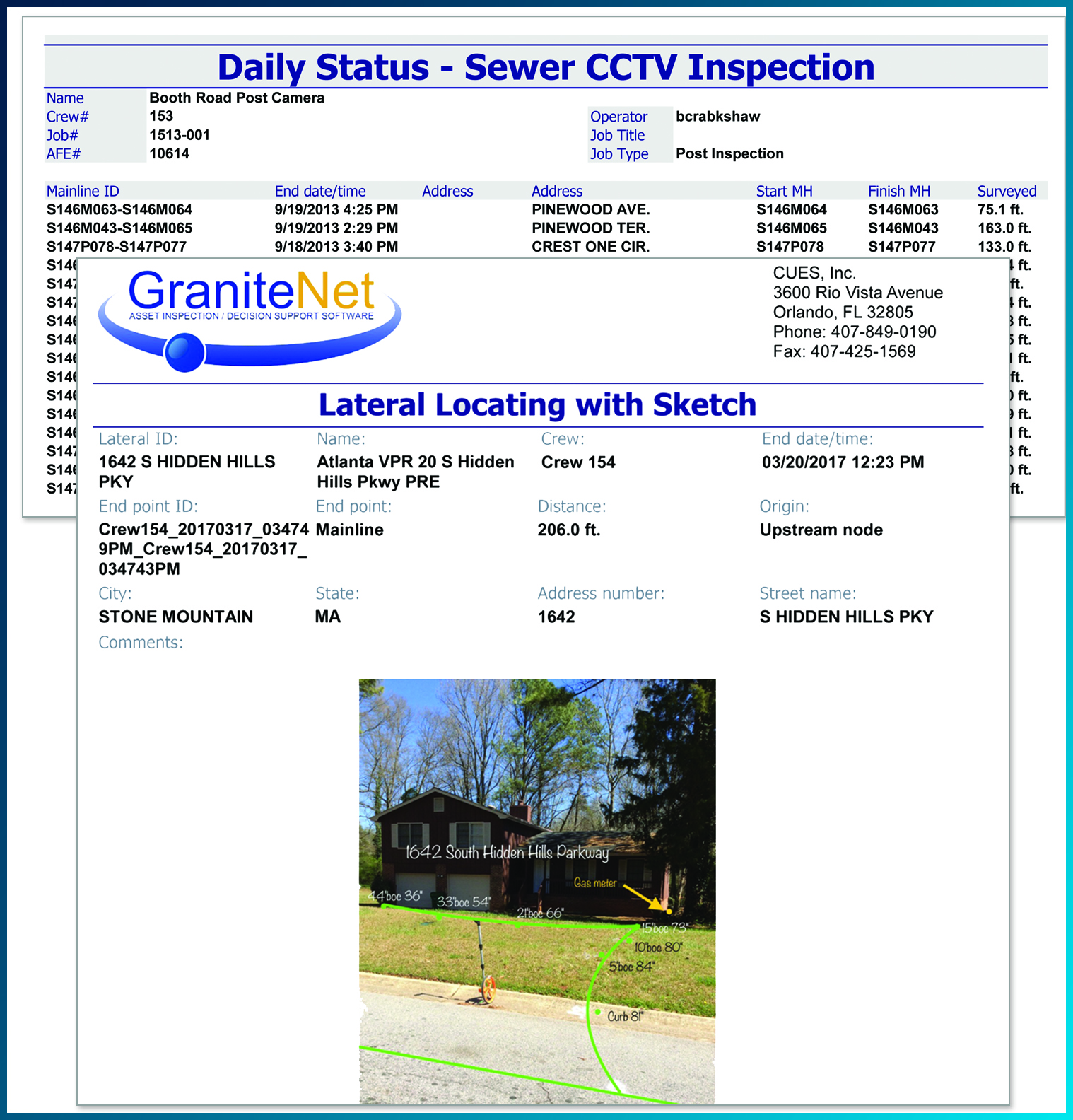

Inspect, Assess & Complete

- Use standardized forms for specific tasks

- Assess infrastructure, collect video & images

- Create digital pipeline Sketch Cards

|

| |

|

|

|

|

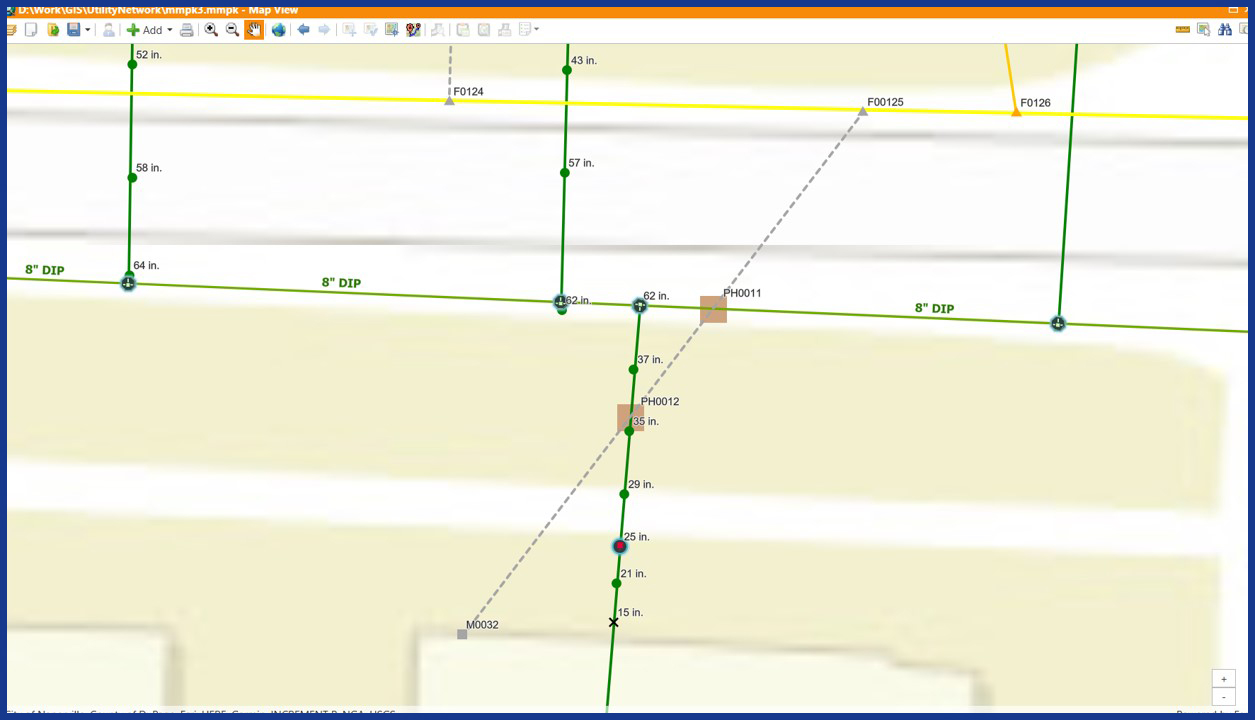

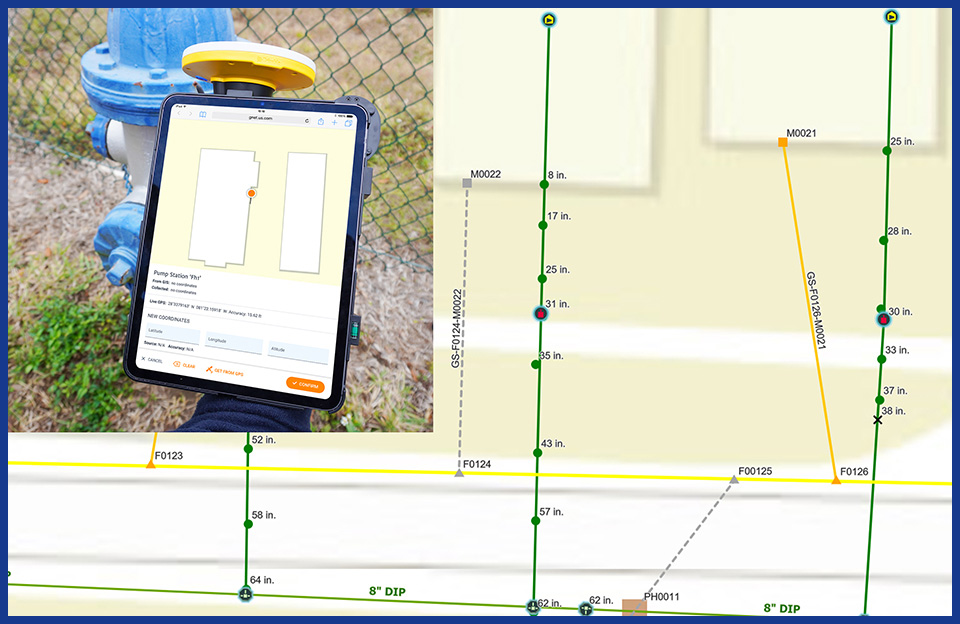

Use & Create Maps

- Reduce dependency on spray paint and flags

- Use existing ArcGIS map documents

Create dynamic map layers from coordinates

- Captured from GPS receiver

- Manually entered

- Estimated from the map

- Export to Google KML map files

Avoid doing re-locates on the same addresses

|

| |

|

|

|

|

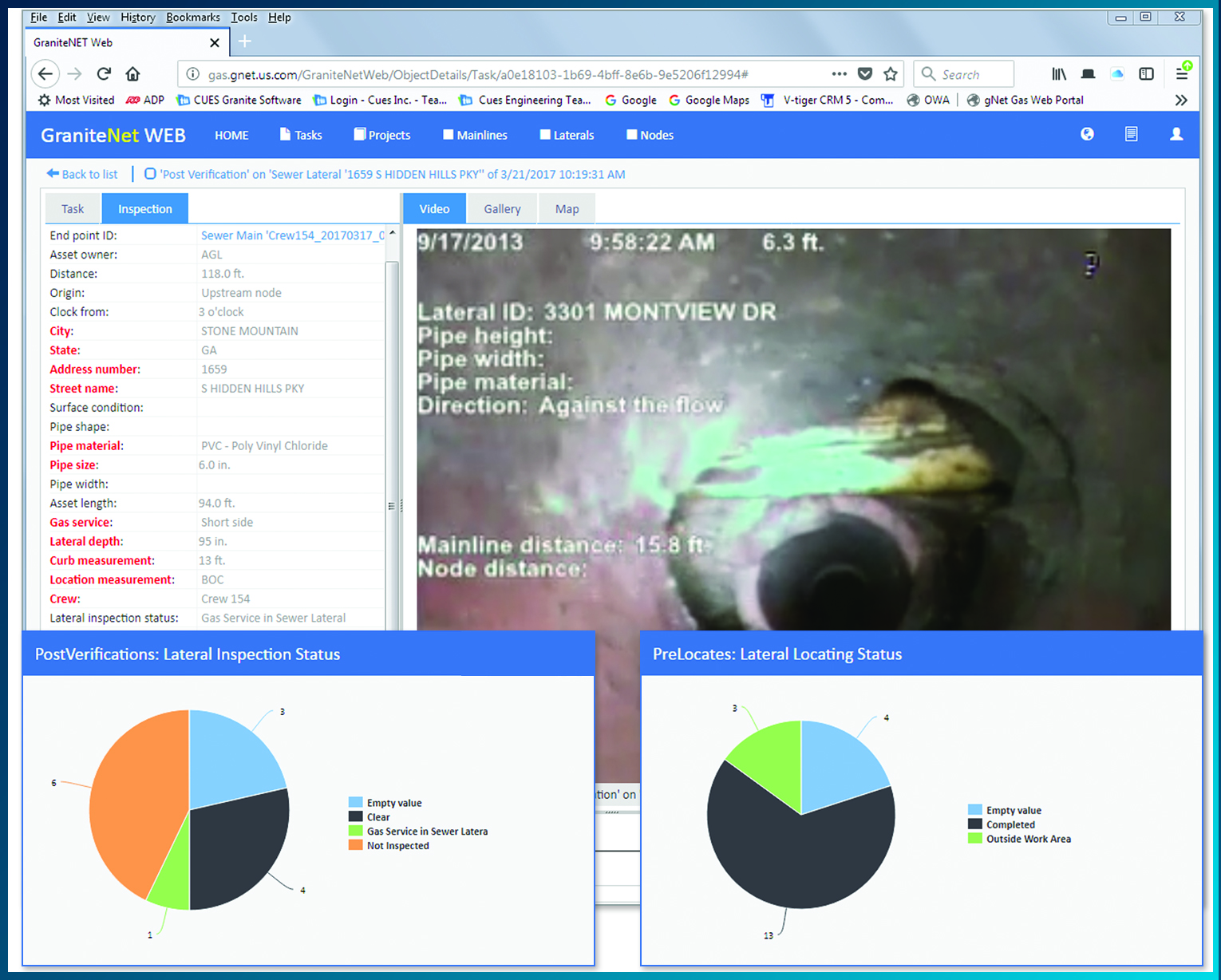

Archive & Store

- Retain all inspection data and media in an indexed and searchable repository

- Archival provides utility indemnification and also enables ongoing risk analysis accessible through the web

|

| |

|

|

|

|

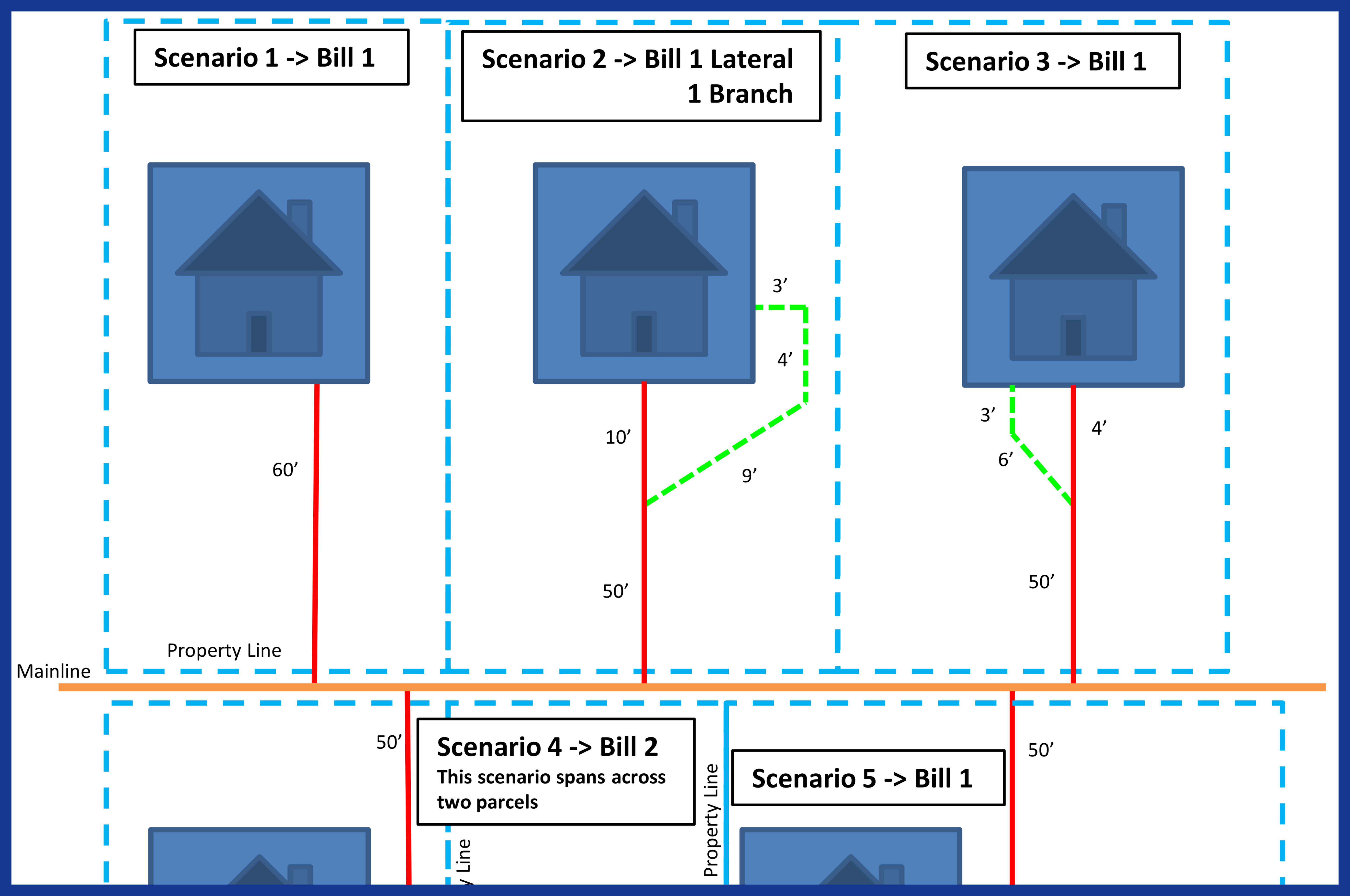

- Audit proper procedures and their billings; Reconcile completed work easier for faster invoice-to-payment lifecycles

|

| |

|

|

|

|

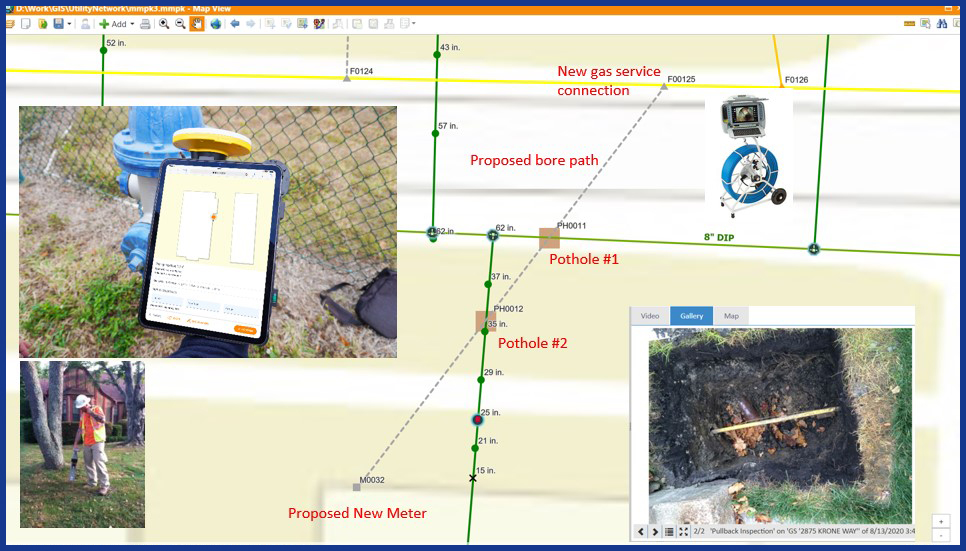

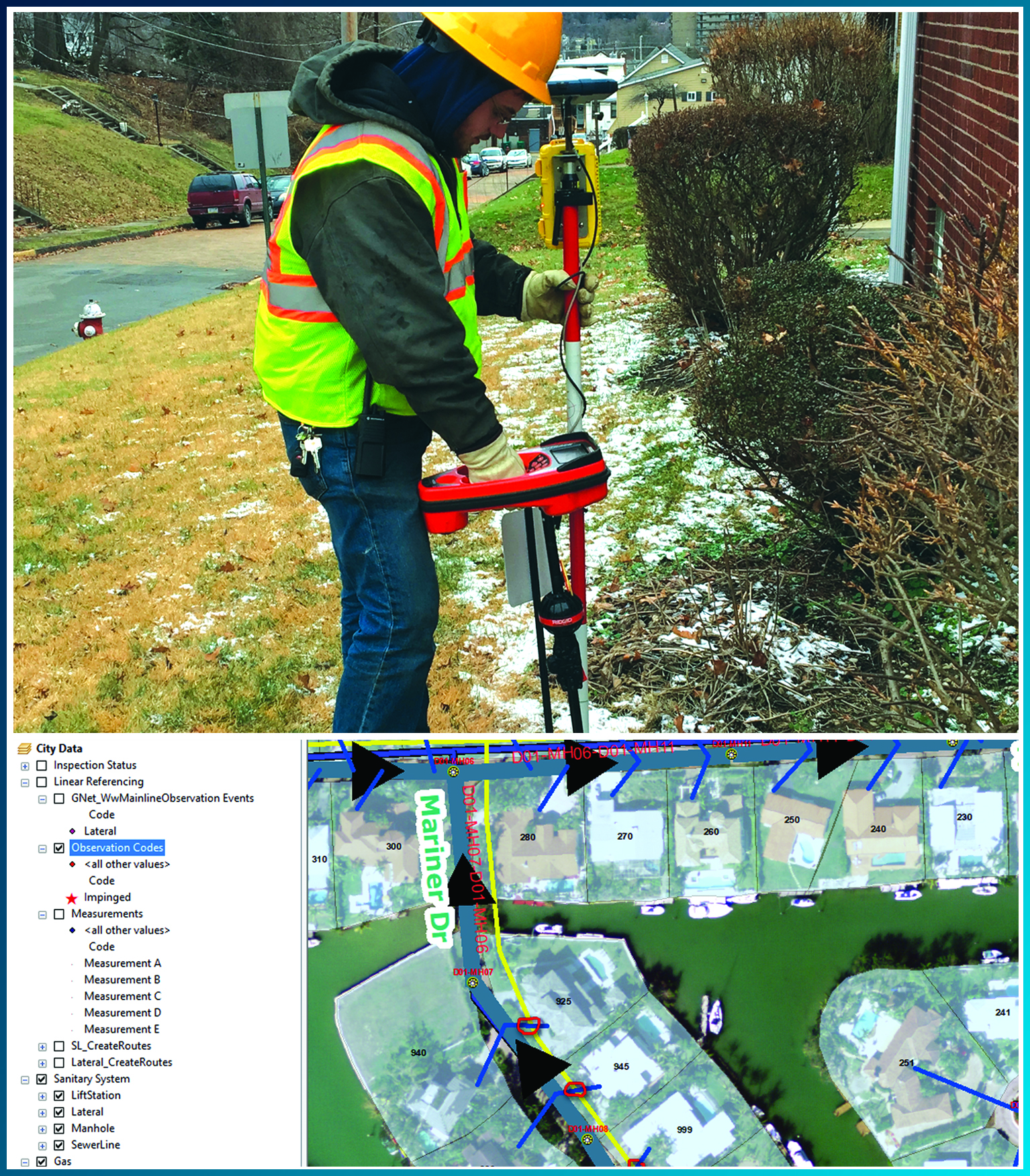

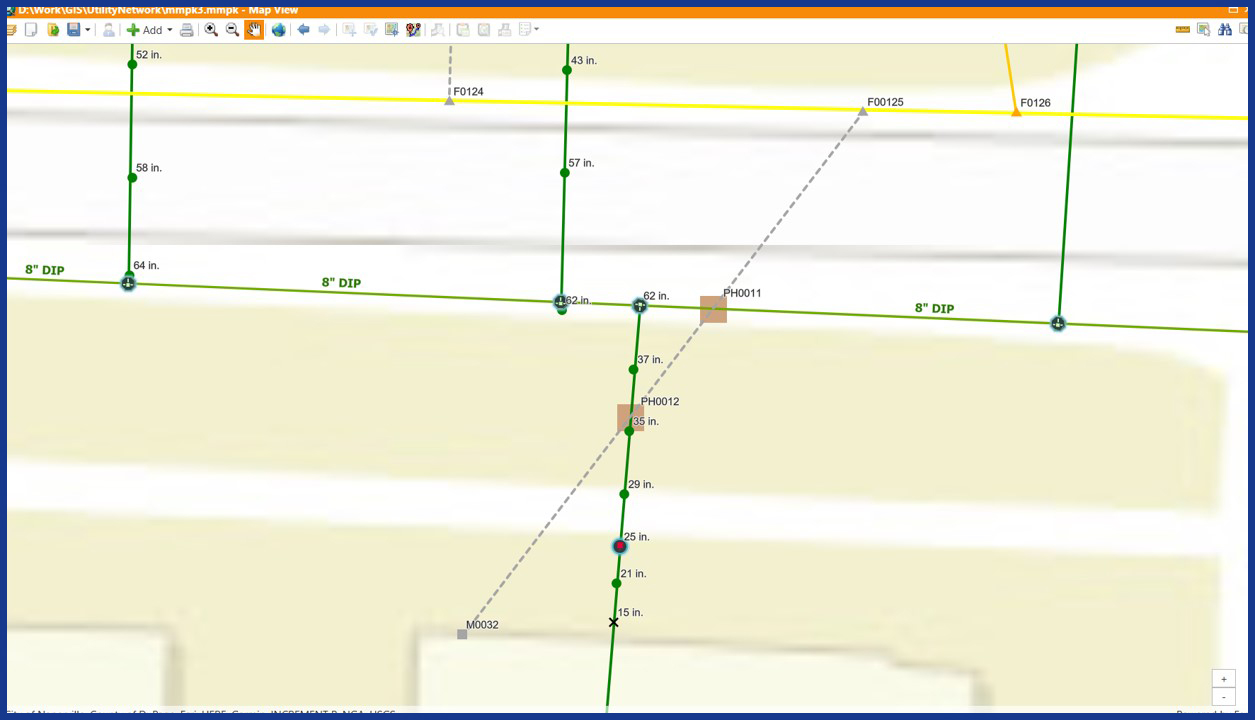

The image on the left depicts the precision of combining CUES' pipeline inspection equipment, software, and GPS to follow strict damage prevention procedures for safer, higher productivity. |

| |

|

|

|

|

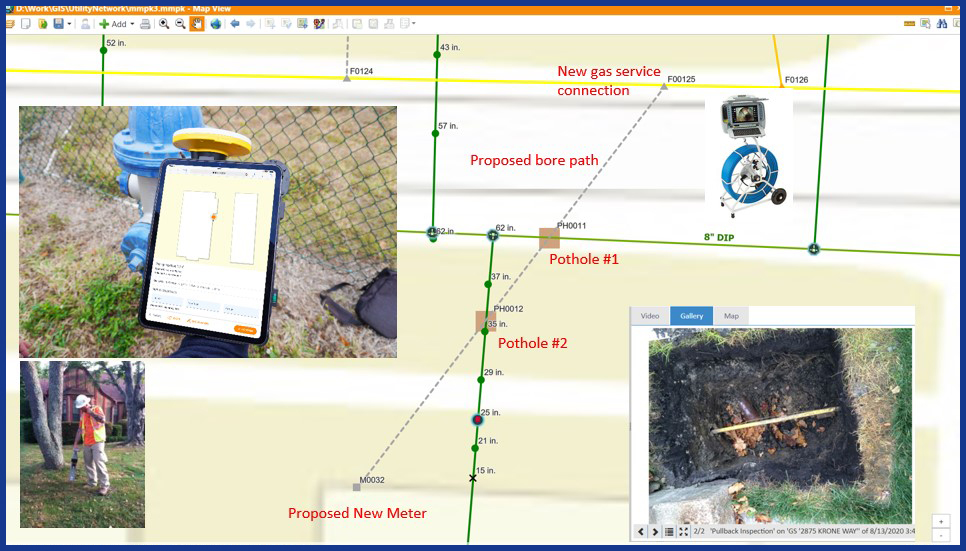

Maintain procedural requirements through spatial precision:

- Mandatory potholing/daylighting with GPS, depths and photos are collected when drilling must cross paths with existing utilities. The two brown squares indicate potholes that were required and done during the HDD process to document safety.

|

| |

|

|

|

|

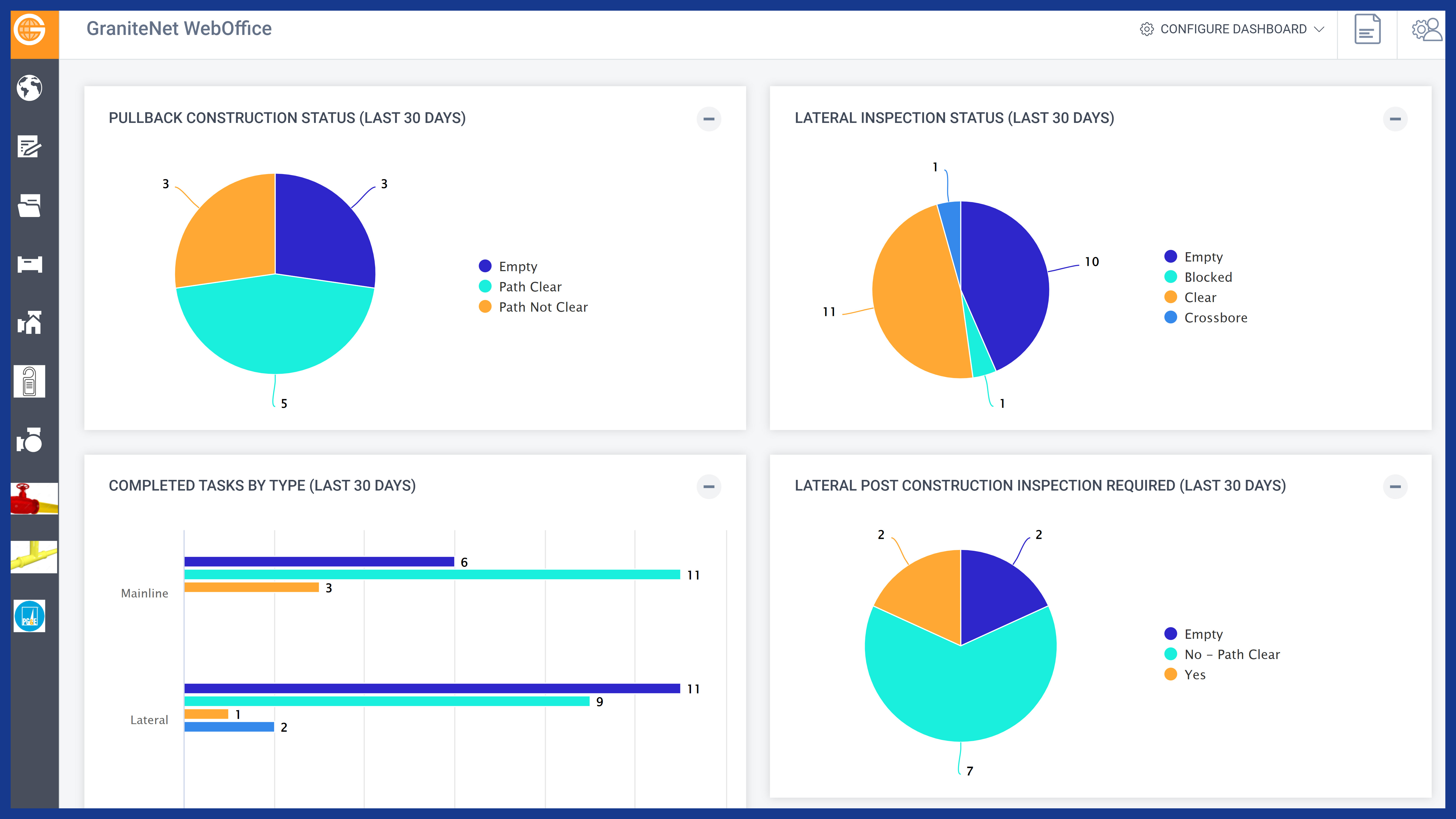

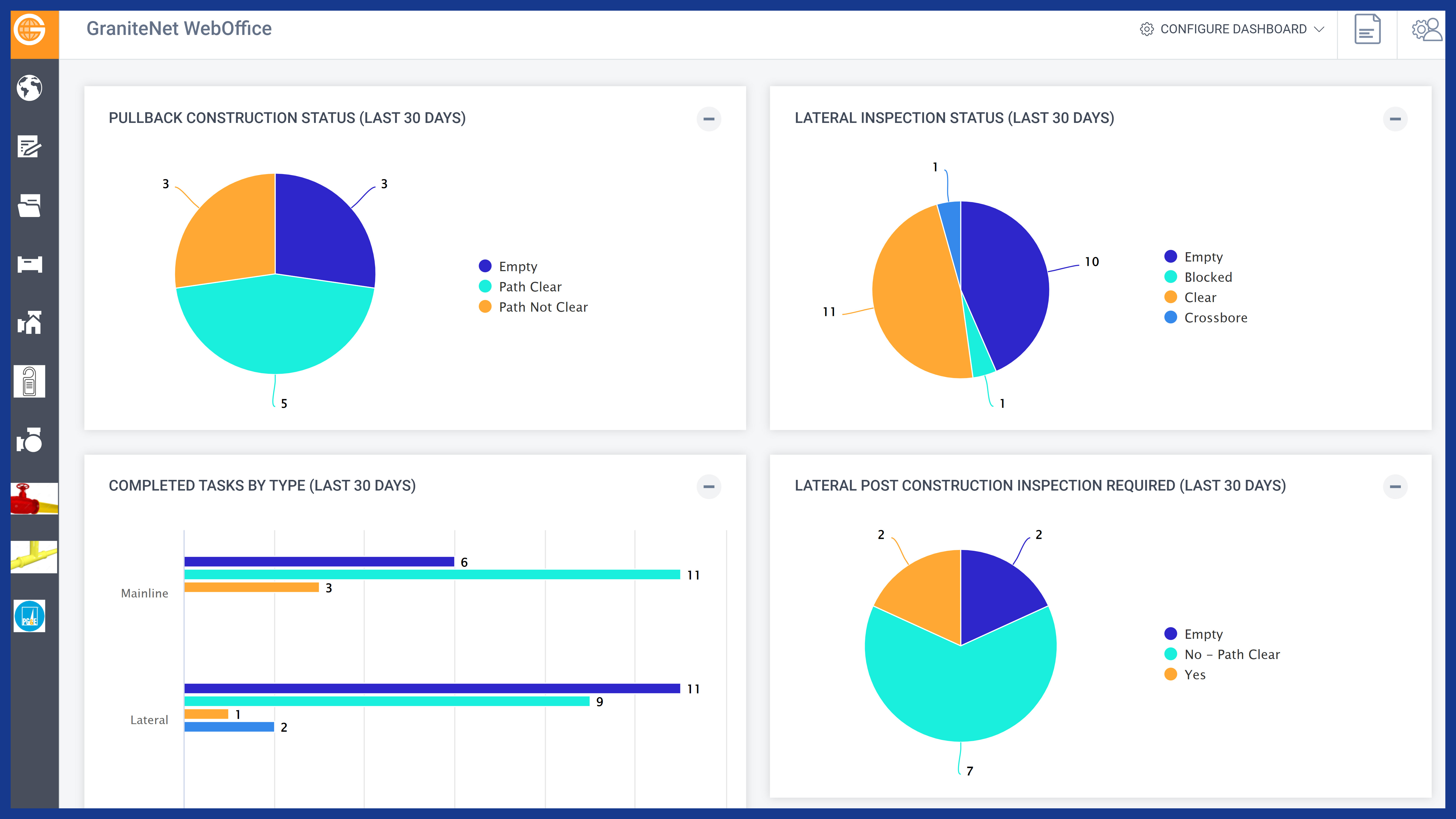

- Track statuses in real time with web dashboards for full views into productivity.

- Information is available from ANY browser device for field crews to update statuses, transmit video, GPS coordinates, photos, etc.

|

| |

|

|

|

|

Report & Analyze

- Generate out-of-the-box custom reports

- Easily create daily summary reports

- As PDF, Excel, HTML, email, etc.

Query data to perform

- Productivity and Status Results

- Deliverables for reconciling

- Payments

- Sophisticated risk analysis algorithms

|

| |

|

|

|

|

- Inspect gas mains to see live or capped gas connections to assess the need for locating on the parcel.

|

| |

|

|

|

|

- Capture Centimeter accuracy GPS coordinates easily for any feature required. Archive both GPS & images for potholes required for safety compliance & to reduce open trenching.

|

| |

|

|

|

|

- Manage HDD drilling by capturing video from CCTV pulled back through the drill path to verify safe, clear bores.

|

| |

|

|

|

|

- Artificial Intelligence to identify risk, Final QA inspections, archival and storage for indemnification

|