News

Every day, inflow and infiltration (I&I) cause water treatment plants to work harder than intended. In fact, research shows that up to half of all flow in treatment plants stems from I&I, and this estimate only worsens over time as municipalities delay repairs.

That excess flow creates unnecessary strain, wear, and tear on your sewer systems, ultimately leading to reduced performance at higher costs.

Cutting down on sewer infiltration is a critical step in reducing excess expenses, and one of the most cost-effective strategies is pipeline grouting—the act of remotely filling leaks with grout and chemicals to reduce I&I for years to come.

How Does Pipeline Grouting Work?

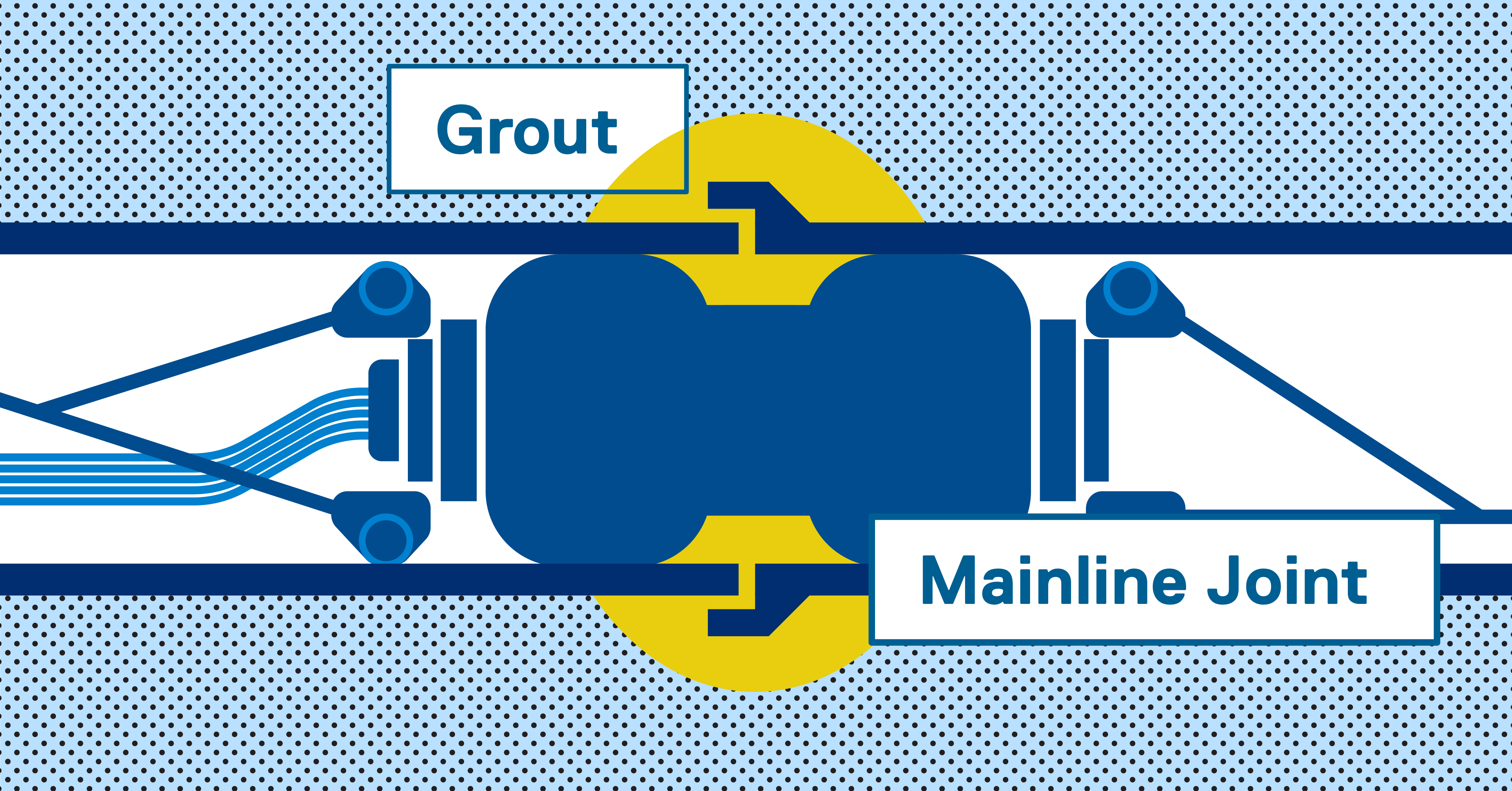

Pipeline grouting is a safe, effective solution to cracks and voids in mainline joints, service connections, service laterals, and even manholes.

No matter where the sewer grouting is applied, the method used is nearly identical:

- A CCTV-equipped machine called a “packer” is directed through the pipeline until it is centered over the problematic area.

- End bladders on each end of the packer are inflated until they’ve created an airtight seal inside the pipeline.

- Compressed air is released between the bladders. If the compressed air leaks, an issue within the pipeline is confirmed.

- The packer pumps grout between the inflated bladders and into the broken joint or pipeline.

- The grout combines with the surrounding dirt, rocks, mud, and sediment to create a leak-tight seal and provide improved pipe support.

- Another air test is performed. If no air leaks, the grout has successfully sealed the pipeline, and the packer can be removed.

4 Benefits of Pipeline Grouting

1. It’s Cost-Effective

Pipeline grouting is one of the few pipeline solutions that allows you to directly measure the ROI of your actions. In many cases, the ROI is significant.

Miami-Dade County in Florida, for example, experienced dramatic inflow in its pipelines and found that every $1 spent in pipeline grouting resulted in $2.50 in savings for its overall water treatment system, as 128 million gallons of additional flow is now no longer flowing to the treatment plant.

2. It Stops Leaks

Of course, the biggest benefit of pipeline grouting and grout systems is their ability to eliminate leakage. When half of all I&I is excessive flow from unintended sources, blocking the excess can cut costs and relieve treatment centers from extra strain.

3. It Stops Subsidence

Because pipeline grouting completely encases the joint, connection, lateral, or manhole, it provides additional external support that can prevent the pipe from moving while stabilizing the structure.

4. It’s A Long-Lasting Solution

Under the right conditions, sewer grout has a 200-year half-life, and we’re even working toward offering a 50-year guarantee on our pipeline grouting solution. At a minimum, though, you should experience decades of leak-free performance from your grouting repair.

CUES’s Tools For Pipeline Grouting

At CUES, we provide a wide variety of reliable pipeline grouting systems and solutions, including:

1. Easy Grout Control System

The Easy Grout Control System software delivers an easy-to-use program for deploying packers and sealing pipeline leaks from the comfort of your mobile workstation. With the Easy Grout Control System, you’ll unlock benefits such as:

- Automatic calculations to determine recommended settings based on field conditions and pipe size

- Automatic totalization of grout volumes pumped per joint per job

- Graphical, real-time display of current void pressure

2. Packers

Our Low Void Packers are designed to save time, labor, and money over their lifespan. The Low Void Packers offer a low profile design to minimize grout ring residue and deliver acrylamides, urethane, and other common chemical grouting materials.

3. Custom Grout Inspection Vehicles

Our Custom Grout Inspection Vehicles equip your team with reliable mobile technology for cost-effectively eliminating leaks in sewers, manholes, tanks, vaults, tunnels, and other applications.

Learn More About Pipeline Grouting

To learn more about pipeline grouting and our suite of water, wastewater, and stormwater equipment, contact us.