News

For many of the municipalities we work with, manhole inspections aren’t always their first priority. Although they may have hundreds or even thousands of manholes, competing priorities push manhole inspections to the bottom of their to-do lists—especially since manhole inspections can be so time-intensive. But leveraging manhole inspection equipment and software can make it easier.

With the proper equipment, your team can move beyond the Level One inspection of peering down the manhole with a flashlight and clipboard and instead utilize state-of-the-art technologies that quickly map the manhole and store necessary inspection data for future reference.

Read on to learn more.

Why Manhole Inspections Are So Important

When a manhole fails, the results can be costly. In addition to suffering a damaged reputation, municipalities often pay $250,000 to $500,000 to fix or replace a manhole, and fines from the EPA can increase these overall expenses even more.

In general, manhole inspections help municipalities identify and prevent three types of failures:

1. Blockages. When a manhole becomes blocked at the bottom or in nearby pipe, sewage and other debris can overflow onto the pavement, potentially leading to hazardous conditions or fines from the EPA.

2. Structural Failures. Corrosion and erosion can wear away at manholes over time. When left unrepaired, a manhole can fail and turn into a dangerous sinkhole, which can shut down an entire street as repairs are made. These sinkholes are costly to repair, and they can negatively impact the local economy as traffic flow is disrupted.

3. Leakage. When too much water enters the system, either via rainwater or groundwater, water treatment plants work extra hard, and this may necessitate upgrades or building a second plant. Both of these are costly choices, and they could even increase annual taxes for local residents.

Regularly inspecting manholes can catch and prevent these issues from occurring.

Types of Manhole Inspections

We generally think of manhole inspections in three different ways, and each one has its own advantages and disadvantages.

Your options:

1. No Inspection. The first option is to ignore your inspection schedule entirely and hope for the best. This is never something we recommend, as ignoring your manholes can lead to costly repairs later on.

2. Level One Inspection. According to the Manhole Assessment Certification Program (MACP), a Level One inspection provides a high-level overview of a manhole’s current condition.

During a Level One inspection, a worker looks down the manhole and visually inspects for cracks, damage, blockages, and other issues. They’ll then record their findings on a clipboard, and this data will then be typed into a database back at the office later on.

While this inspection is relatively quick, it’s a labor-intensive strategy because of the manual data entry, and it’s also imperfect. Without climbing into the manhole and inspecting it up close, an individual could miss important information that could prevent long-term issues.

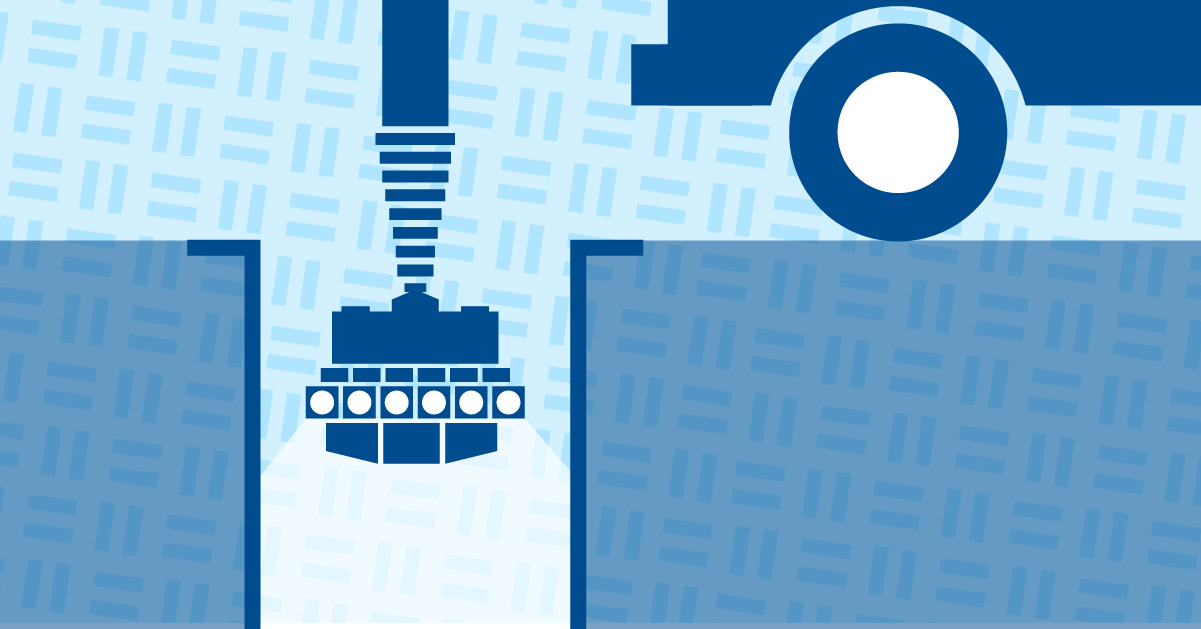

3. Level Two Inspection. A Level Two inspection delivers much more detailed data than a Level One inspection.

During a Level Two inspection, workers frequently use manhole inspection software to inspect and record the interior of a manhole and digitally capture data. While the upfront investment is greater than the cost of a clipboard and flashlight, these more advanced methods can make inspections faster and allow for more inspections in a single day.

Learn more about Level Two inspections in our CUES Webinar: The Benefits of MACP Level II Manhole Inspections.

In addition, manhole inspection equipment is designed to deliver more accurate results that can help municipalities make informed decisions about repairs and investments for their manholes.

Read the next section for a full list of advantages of using manhole inspection equipment!

Advantages of Using Manhole Inspection Equipment

Manhole inspection software and equipment provides a wide range of benefits, including:

1. Increased inspection speed. Today’s inspection equipment can be just as quick as someone peering down a manhole with a clipboard. But the real-time savings comes in the data collection and storage. Many of today’s tools can automatically input data, removing the tedious task of data entry.

2. Improved accuracy. Manhole inspection equipment provides a closer look at the manholes, which provides greater analysis. In addition, the data collected can be automatically added to the system, removing the potential for human error.

3. Improved data collection. Manhole inspection scanners and equipment are becoming more and more sophisticated every year, and top-of-the-line options can even generate 3D scans for up-close team analysis later on. These scans can also help teams track long-term manhole performance and degradation, potentially improving repair schedules and preventing major failures later on.

Manhole Inspection Equipment Options

At CUES, we offer a wide variety of manhole inspection equipment. Options to know:

1. QZ3. The QZ 3 is an inexpensive option for quick, effective manhole inspections. With the QZ 3, you can reach deep inside a manhole with a camera as the video syncs with your tablet or phone. You can then embed the video into your inspection document, enhancing your overall records. The QZ 3 is an excellent low-budget option that’s perfect for storing in the back of your vehicle until it’s required for an inspection.

2. DUC Manhole Inspection Camera. Our Digital Universal Camera (DUC) attaches to an adapter for vertically inspecting manholes.

3. SPiDER Scanner. Our Spherical Imagery Digitally Enhanced Rendering (SPiDER) Scanner creates a 3D model of your manhole by crawling five feet per minute. In the process, the SPiDER Scanner creates a color map of the manhole’s interior, calling out imperfections and potential problem areas. All data is backed up in the cloud, and you can compare maps from year to year to track the manhole’s structural integrity over time.

4. Manhole Deployment Systems. Our manhole deployment systems provide telescopic boom systems for your municipal trucks, allowing you to lower a camera deep inside for up-close inspections.

5. Manhole Inspection Vehicles. Our manhole inspection vehicles provide everything you require in a single van—ample storage for tools, proper equipment, and even a fully equipped office to track manhole data.

Learn More About CUES Manhole Inspection Equipment

To learn more, check out our selection of CUES Manhole Inspection Equipment, or contact us or your CUES Regional Sales Representative or authorized dealer. We’ll help you pick the perfect tools for your budget, inspection schedule, and data needs.